Why Basket Strainers are important?

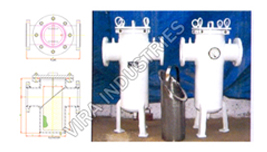

Perfect Ventures provide Basket Strainer which is used to remove dirt and takes out the unwanted material from the fluid.

We, Perfect Ventures have fabricated & commissioned these strainers with Rotor & motor assembly with self-cleaning for viscous fluids such as fibrous solutions, pulp. Basket Strainers have various automation considering the process requirements.

Basket type strainers come with a jacket for heating considering the application where there is a possibility of liquid getting solidify like LDO, FO & Molten Sulphur.

The Basket Strainer is available in various materials with a jacket suitable for the pressures & temperature.

Features:

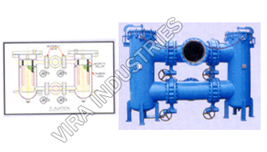

These Basket Strainers comes in Simplex and Duplex type depending on the process requirements.

These strainers have standard features like diverting valves, flush, drain connections with ball valves.

Basket Strainers can be offered with PERMANENT MAGNETS which can easily separate magnetic dust from the liquids. Strainers are recommended in Steel plants, Rolling Mills, Mining Industry and Automotive Industry.

Specification:

Basket Strainers are normally recommended for a continuous process application.

| Basket Strainer | Simplex/Duplex Type |

| Size | 15NB to 2000NB |

| End Connections | Flange to ANSI,BS,JIS,DIN std./BWE |

| Pressure Class | CS/SS304/304L/316/316L/Duplex SS/Rubber lined/PTFE coated/FRP lined, fabricated version |

| MOC | Up to 600# |

Basket Strainers can also be offered with Self-cleaning attachment/ Permanent Magnets/Jacketed.